Who We Are

Sonics & Materials, Inc.

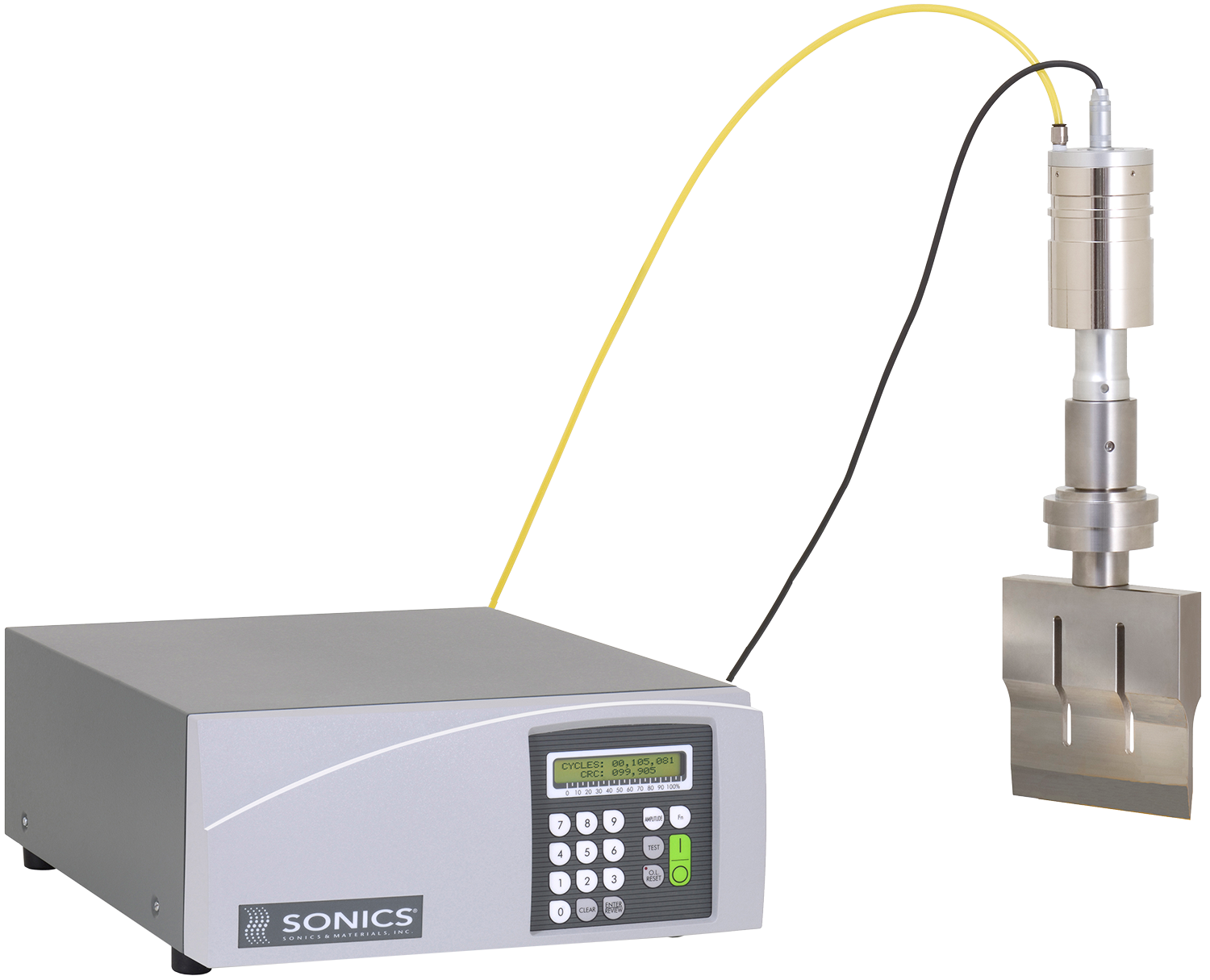

Leaders in Innovative Ultrasonic Technology

Since its inception in 1969, Sonics & Materials, Inc. has enjoyed over 5 decades of world leadership in the fields of liquid processing and ultrasonic welding, sealing and cutting technology. The company is ISO 9001:2015 certified by DQS Inc. and is consistently in the vanguard of industry innovators. Leading the way in research and applied technology, Sonics is dedicated to providing the highest quality products and real world manufacturing solutions, backed by comprehensive technical support and applications expertise.

Our Mission

Sonics’ mission is to lead the industry in delivering superior technology and high-performance products backed by unmatched customer support, while sharing with our business partners and customers the unique ultrasonic knowledge bank that we have acquired over 5 decades. Sonics also looks to advance the industry further by cultivating an environment that fosters the spirit of innovation and creativity upon which the company was founded.

Advancing the Field of Ultrasonic Technologies

Sonics was founded in 1969 by Robert Soloff, following his breakthrough discovery of the ultrasonic method for welding rigid thermoplastic parts. From the beginning, his vision was to build a company that would push the boundaries of ultrasonic technology while designing and manufacturing precision equipment. As a pioneer in the field, Mr. Soloff fosters an atmosphere of innovation and curiosity. He welcomes emerging engineers, encourages scientific collaboration, and has built a culture where new ideas can thrive. That spirit continues to shape Sonics today.

The company is now proudly led by his daughter, Lauren Soloff, who carries forward his entrepreneurial spirit and commitment to technical excellence. Under her leadership, Sonics operates as a global organization while maintaining the warmth and integrity of a family business. Guided by forward thinking and strong customer partnerships, the next generation is building on a rich history to drive the future of ultrasonic technology.

Our Manufacturing Divisions

SonicsEdge

Delivers Superior Value and Ensures Our Customers’ Success

Comprehensive In-house Manufacturing & Tooling

Sonics’ in-house manufacturing operation is a US-based, ISO 9001:2015 certified by DQS Inc. facility featuring full machine shop capabilities and a state-of-the-art customer applications lab for system development, testing, optimization and production. As a result, we manufacture only top-quality custom and off-the-shelf ultrasonic technologies for customers in diverse industries.

Sonics also provides design and custom machining of ultrasonic tooling, fixtures, probes, flow cells and cup horns. Our in-house manufacturing and tooling capabilities provide these advantages to our customers:

- Quality-controlled prototyping and tooling onsite

- Fast turnaround on ultrasonic systems, parts, components and kits

- Precise manufacturing control

- Ready-made or custom products built to precise specifications

Expert Application Assistance & FEA Diagnostics

Sonics’ ultrasonic engineering experts will work with you to provide guidance, training, and application assistance, or design a new solution to meet your specific objectives – from process optimization, complex integration or adapting new technologies. We value our customers and the importance of keeping your business operating at peak efficiency.

Sonics maintains a fully equipped lab to test customer applications and processes, and we conduct computer modeling with 3D finite element analysis (FEA) to simulate real-world conditions and identify potential problems before they occur in the field. Our ultrasonic application engineering expertise allows us to:

- Design to optimal specs prior to manufacturing

- Assess ultrasonic vibration frequency, amplitude and stress

- Identify stresses, predict performance, and analyze part failures

- Troubleshoot and diagnose a malfunctioning or underperforming application

Unmatched Customer Support

Your business is our top priority and the reason why we provide unmatched consultative and engineering support services that can meet all your application needs.

From the moment you become a Sonics customer, a dedicated team will shepherd your project through from application assistance and design, comprehensive product testing, systems integration and troubleshooting. Onsite field service is also available, with access to the people who created the technology you are using. Once deployed, Sonics provides ongoing support through:

- Our global sales and distribution network that guarantees our customers access to fast, responsive support anywhere

- Ongoing training seminars by specific system, and by basic and advanced plastic and ultrasonic assembly methods

- Substantive white papers and protocols for specific ultrasonic applications

Rigorous Quality Control

We have made substantial investments in our systems, processes and operations because making a top quality product is top of mind for all Sonics employees. We are a US-based, ISO 9001:2015 certified by DQS Inc. manufacturer with in-house tooling capabilities and a high-tech ultrasonic applications lab onsite. Our products are CE compliant and TUV certified. Because we control every step in the production process, we make extremely reliable ultrasonic technologies that perform at a near zero failure rate in the field. For Sonics customers, our rigorous quality control assures:

- Ultrasonic technologies that perform consistently, repeatedly and accurately

- Highly reliable product operation in the field (less than 1% failure rate)

- Industry leading warranties – such as our 3 year warranty on parts/labor for Sonics high intensity liquid processors