Cup Horns

The cup horn can process multiple sealed tubes or vessels at one time without contact with an ultrasonic probe. This method eliminates cross contamination, sample foaming, overheating and aerosolization which can all occur when using a probe. Most importantly the cup horn enables samples under 200μl to be effectively processed.

The cup horn is attached to the converter in place of a probe, and filled with water. Microtubes containing samples are placed inside using specially designed tube holders. Ultrasonic energy is transferred through the water and into the sample tubes. Multiple tube holders are available for various size tubes and vessels.

Inlet and outlet ports enable cold water to be circulated within the cup, inhibiting heat build up during extended operation. Use of the chiller is highly recommended and due to the high noise level created by the cup horn, a sound abating enclosure is required.

Note: Selecting the appropriate size and type of sample tube will greatly improve results. Contact Sonics for application assistance.

Cup Horn Accessory

Part No.

630-0731

VCX500 with Cup Horn, Chiller, Enclosure Package

Part No.

VCX500CCE

TUBE HOLDER OPTIONS

8 x 1.5mL

POLYSTYRENE TUBES

Part No.

830-00247

8 x 1.5mL

POLYPROPYLENE TUBES

Part No.

830-00248

12 x 0.5mL PCR Tubes

Part No.

830-00245

1 x 15mL TUBE

Part No.

529-0029

1 x 50mL TUBE

Part No.

529-0030

Part No. 830-00247 and 830-00248 tube holders are included with the cup horn.

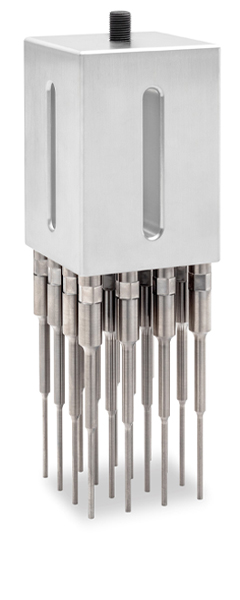

Multi-Element Probes

The high throughput multi-element probes increase productivity and minimize repetitive tasks by processing numerous samples simultaneously. Units are available with 4, 8, 16, and 24 tips and are compatible with either the 500 or 750 watt systems. Custom formatted multi-element probes are available upon request. The replacement tips are PART NO. 630-0660.

Tip Diameter

1/8" (3mm)

Volume

0.5-15mL

Amplitude

120μm

4-Element

Part No.

630-0559

8-Element

Part No.

630-0586

16-Element

Part No.

630-0699

24-Element

Part No.

630-0579

The heavy duty stand with lab jack is recommended for use with each multi-element probe unit.

Part No.

830-00130

Flow Cell

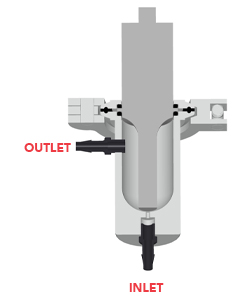

Medium Volume Continuous Flow Cell

The flow cell enables continuous processing of 1L or greater volumes. The process fluid enters through the inlet at the bottom of the unit. As it passes through the cavitation field, it is ultrasonically processed. The fluid exits the unit through an outlet port. The intensity and extent of processing are controlled by adjusting both the flow rate and amplitude setting.

A 1/2" (13mm) solid tip flow cell probe is included and the volume of liquid inside the chamber with the probe installed is 65mL. A variable speed pump is recommended but not included.

Flow Cell Assembly

Part No.

630-0651

Replacement Probe

Part No.

630-0644

Specifications

Material

316L stainless steel

Height

9.1" (231mm)

Diameter

3.5" (89mm)

Maximum Flow Rate

0.5L/min.

Max. Operating Pressure

100psi

Internal Volume w/Probe

65mL

Product/Coolant Connectors

hose barbs for 1/4" ID tubing

Sound Enclosures

Ultrasonic processing produces high pitched noise, which originates from the vessel walls and the liquid surface. The sound enclosure reduces the noise to comfortable levels. A support rod and converter clamp are included. Access ports are available on both sides and the top of the enclosure.

Outer Dimensions

(H x W x D) 301/2" x 131/2" x 13" (775 x 343 x 330mm)

Inner Dimensions

(H x W x D) 29" x 121/2" x 12" (737 x 318 x 305mm)

Part No.

830-00427

Support Stand

Securely support your ultrasonic processor with a chemically resistant plastic holder on a 51/2" x 9" cast-iron base with 1/2" diameter rod.

The converter clamp and support stand can be ordered separately.

Part No.

830-00459

Part No.

830-00116

Part No.

830-00109

Sonochemistry Equipment

The chemical effects of ultrasound are diverse and include dramatic improvements in both stoichiometric and catalytic reactions. In some cases, ultrasonic treatment can increase reactivity by nearly a million-fold. It does so through the process of acoustic cavitation; the formation, growth, and implosive collapse of bubbles in a liquid.

During cavitational collapse, intense heating of the bubbles occurs. The localized hot spots have temperatures in the range of 5000°C, pressures approaching 500 atmospheres, lifetimes of a few microseconds, and heating and cooling rates greater than 109K/s. Of special interest for sonochemistry research, is the fact that cavitation generates highly reactive free radicals that greatly enhance chemical reactions.

Applications for chemical reactions exist in both homogeneous liquids and in liquid-solid systems. Ultrasound has also been found to be beneficial for the initiation or enhancement of catalytic reactions, in both homogeneous and heterogeneous cases.

The adapter Part No. 830-00014 screws onto the special probe Part No. 630-0217 at the nodal point. The glass chamber slides onto the adapter and is secured in place as the bushing is screwed into the chamber compressing the O-ring. Moving the glass chamber up or down on the adapter allows the portion of the probe protruding out of the adapter to be immersed at the optimum depth into the sample.

Sonochemical Reaction Accessories

4-10ML Reaction Vessel

4-10mL reaction vessel. Two 14/20 side necks. Supplied with bushing and O-ring. Glass chamber height: 4 7/8" (123mm).

Part No.

830-00011

10-50ML Reaction Vessel

10-50mL reaction vessel. Bottom well capacity: 10mL. Main body capacity: 50mL. Two 14/20 side necks. Supplied with bushing and O-ring. Glass chamber height: 4 3/4" (120mm).

Part No.

830-00012

40-250ML Reaction Vessel

Three 14/20 side necks. Supplied with bushing and O-ring. Glass chamber height: 6 3/8" (162mm).

Part No.

830-00013

Adapter

5" (127mm) long. Stainless steel. Internally threaded. Threaded onto a full wave 10" (254mm) long 1/2" (13 mm) probe at the nodal point.

Part No.

830-00014

Sonochemistry Probe

1/2" (13mm) special 10" (254mm) long full wave solid probe. Used with the adapter.

Part No.

630-0217

General Accessories

HEAVY DUTY SUPPORT ASSEMBLY

Supports the converter and multi-element probe with minimum deflection. Includes lab jack. Recommended when working with any multi-element horn.

Part No.

830-00130

ROSETTE GLASS COOLING CELLS

The rosette is a glass cell that enables uniform treatment at low temperatures. Fill the rosette with your liquid sample and place it in an ice bath. The ultrasonic energy forces the sample to circulate under the probe and through the cooling arms.

300ML Rosette

Part No.

830-00001

30ML Rosette

Part No.

830-00003

JACKETED BEAKERS

The jacketed beaker is attached to a chiller or another cold water source. The chilled water is circulated around the liquid within the beaker maintaining the desired sample temperature.

10ML cooling cell with water jacket

Part No.

830-00009

100ML cooling cell with water jacket

Part No.

830-00010

LABORATORY JACK

Provides adjustable elevation from 2 1/2" (64mm) to 10" (254mm). Top plate: 6" x 6" (152 x 152mm).

Part No.

830-00113

TEMPERATURE PROBE

Enables temperature monitoring from 1 – 100ºC.

Part No.

830-00060

REPLACEMENT CONVERTER

Replacement converter for 750-500 Watt models.

Part No.

CV334

REPLACEMENT CONVERTER CABLE

6' (1.8m) length.

Part No.

201-0300

REPLACEMENT WRENCH SET

The 750 and 500W ultrasonic processors include 2 spanner wrenches and a 9/16" x 7/16" open end wrench.

Part No.

381-0005

HAND HELD FREQUENCY METER

Check the frequency of energized probes, converters and boosters. Frequency range: 10.00kHz - 80.00kHz.

Part No.

833-00012

FOOTSWITCH

For hands-free operation with 10' (3m) cable.

Part No.

830-00004