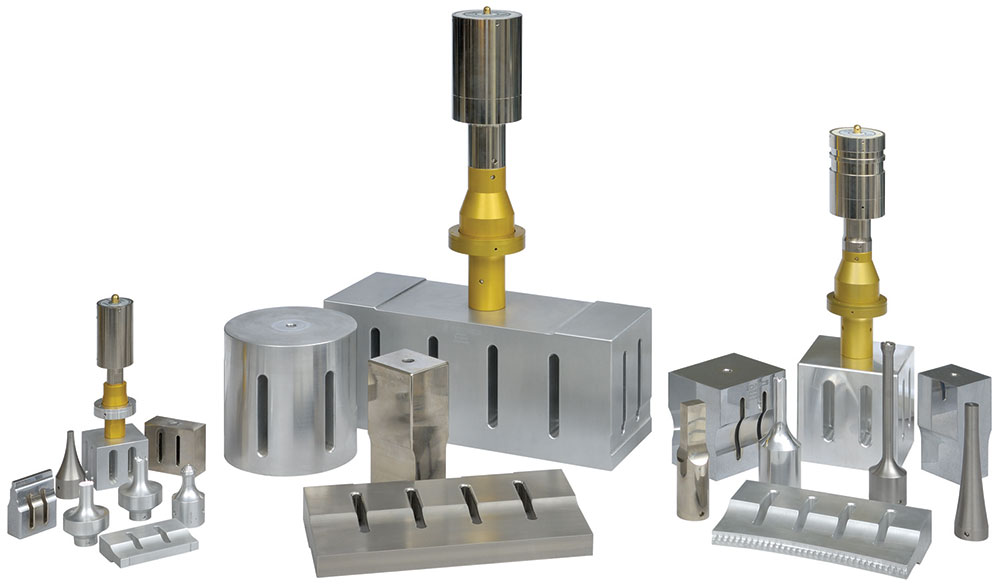

Tooling

Sonics provides design and custom machining of tooling and fixtures for ultrasonic plastic welding, vibration welding, and spin welding, as well as multi-element configurations for spot welding, staking and insertion. Tool fabrication materials include aluminum, titanium, hardened steel, stainless steel and cast polyurethanes.

Ultrasonic Horns

- Ultrasonic horns are designed with an FEA (Finite Element Analysis) simulation program that allows our engineers to observe the vibratory action of the horn prior to fabrication

- Segmented and adjustable fixtures are built to ensure a secure fit with the molded plastic parts

- Contoured fixtures and tools for irregularly shaped parts

- Ultrasonic horns are inspected for even amplitude

- For added strength and durability, carbide facing or chrome plating is applied

- Peripheral devices to clamp, hold and align opposing parts are also available

Customers can submit application files in the following formats and media

Formats (in order of preference):

- ProE

- STEP

- IGES

- AutoCAD (DWG, DXF file formats)

Media:

- Email (Please ZIP any files larger than 10 meg)

- Sonics FTP Site (Please contact Sonics for upload permissions and instructions)

- CD-ROM / DVD / flash drive

- File sharing services